The dupont greentape 951 low temperature co fired ceramic ltcc material system combines the benefits of multilayer co fired ceramic and thick film technologies to meet the increasing demand for reliable electronics functioning in extreme heat and other harsh environments.

Low temperature cofired ceramic properties.

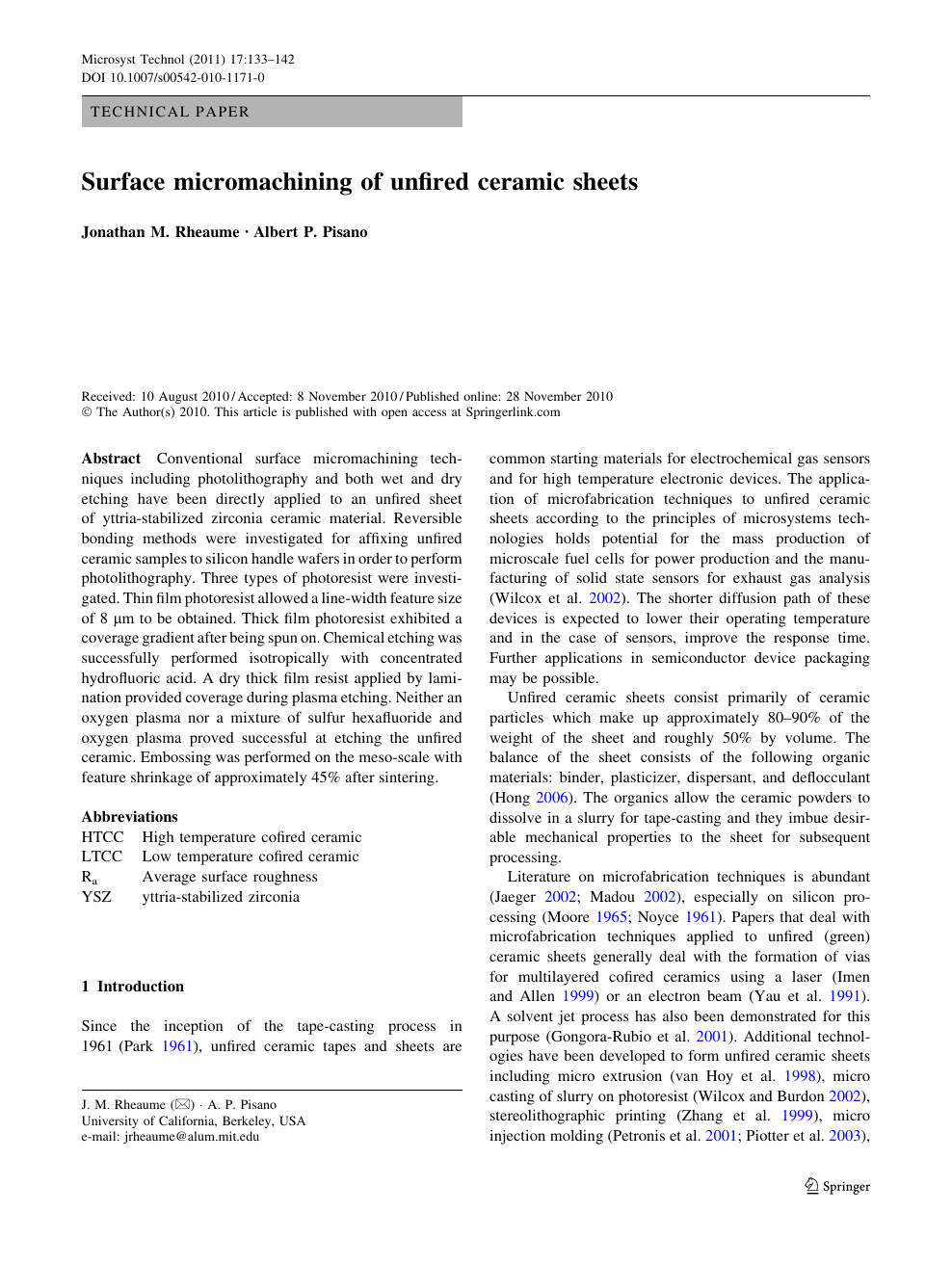

The ultra low temperature cofired ceramic ultcc technology has attracted interest recently because of its efficient energy saving characteristics as compared to the conventional high temperature cofired ceramic htcc and low temperature cofired ceramic ltcc technologies.

Greentape 9k7 low temperature co fired ceramic material system.

Low temperature co firing technology presents advantages compared to other packaging technologies including high temperature co firing.

The x ray diffraction and scanning electron microscopy analysis revealed the coexistence of two phases with different structures owing to their good chemical stability.

This permits the co firing with highly conductive materials silver copper and gold.

The ceramic is generally fired below 1 000 c due to a special composition of the material.

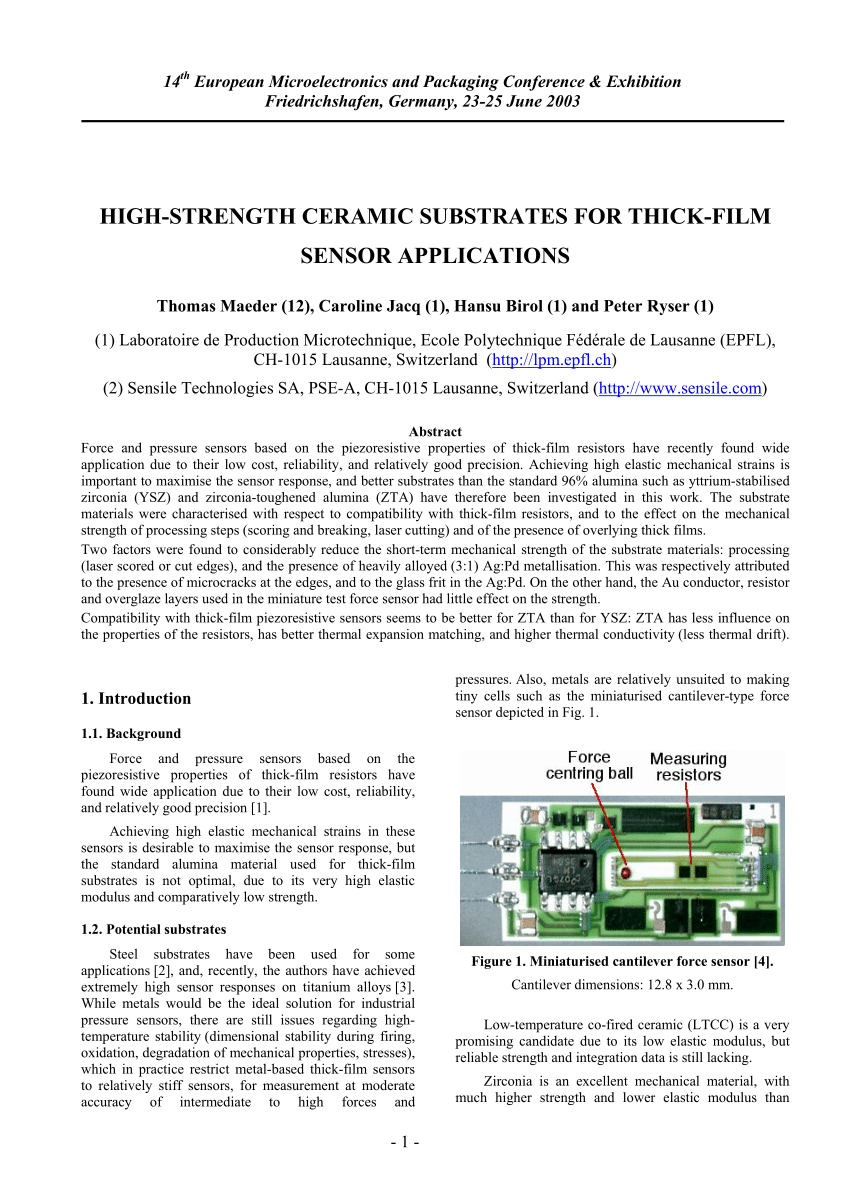

Low temperature co fired ceramic ltcc apitech s ltcc is an alternative glass ceramic multilayer substrate medium that incorporates conventional thick film material metal systems providing a rugged cost competitive substrate that can incorporate embedded passive components along with more advanced devices such as flipchips and wire bonded.

To some extent mn 2 and ca 2 reduced the.

1 the ltcc technology has been the standard technology for the integration of components and substrates.

A low temperature co fired ceramic ltcc device is one of the most rapidly developed integral passive devices which provides a solution to the integration of passive components such as capacitor resistor inductor resonator and filter etc.

The effects of mn 2 and ca 2 on the phase composition sintering behaviors and microwave dielectric properties of limgpo 4 ceramics were studied in detail.

A novel low temperature sinterable 1 x li 2 tio 3 xli 2 ceo 3 x 0 08 0 16 in molar microwave dielectric ceramic was successfully prepared by a conventional solid state reaction method.

Novel low firing microwave dielectric ceramics limg 1 x a x po 4 a mn ca 0 02 x 0 08 with orthorhombic olivine structure were synthesized using the solid state reaction method.

With over 20 years in the ceramics industry sea ceramics has provided substrate solutions that have been made possible through the use of mainstream ltcc ceramics that include formulations by dupont ferro and hereaus.

Sea ceramic technologies is a worldwide supplier of advanced state of the art ltcc and thickfilm substrates and packages.